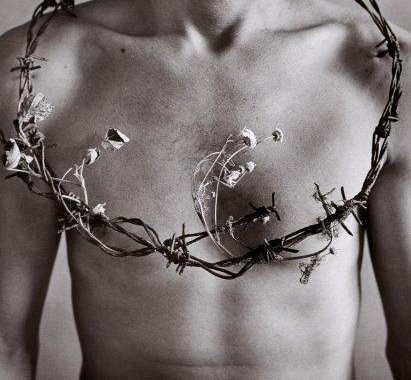

The smallest mechanical miscalculation can lead to a total conflagration of the system. Its part of a larger industrial conspiracy called “planned obsolesces”. Objects are designed to self destruct at the slightest hint that a repair is going to be attempted. In the 1960’s manufacturers came to the conclusion that is they made a washing machine that would last thirty years they would not be able to sell you a new washing machine for another thirty years. No longer satisfied with market growth from expanding legion of consumers created by the post war baby boom, manufacturers decided to shift our attention away from quality and distract us with new features. In the process, planned obsolesces became the primary focus of our consumer economy.

During the last half century the concept of planned obsolesces has continued to evolve. Electronic consumer goods are the perfect example of a product designed to be obsolete the instant the box is opened. It is problematic that manufacturers have become so efficient that they obsolete products before they are sold from the store shelf.

Hewlett Packard is the undisputed king of planned obsolesces. HP design jet printers are essentially carrying case for disposable parts. HP sells or I should say gives a printer to a consumer for less than it costs to manufacturer it. Company profit is in years of selling high priced “consumables” for the printer. Most of the moving parts are designed for only 30 to 60 day life expectancy. During the time the consumer owns the printer they will purchase consumables costing twenty times the original purchase price of the printer. A product designed to sell more products. How more perfect can it get?

For years I have raged a personal war against planned obsolesces. I once ran a Minolta copier eight years past when the company would make parts for it. I ran it four years past when third party overseas replacement parts makers would make parts for it. I ran it two years past when I could find abandon copiers in the nationwide Minolta dealerships. The local Minolta distributor finally offered me a six year old replacement for free, just because they were just tired of repairing my unit. The damn thing would still be running is only Klaus could only figure out how to attach a crank to it.

An unintended result of this planned obsolesces is that we are losing the people who know how to fix things. We are losing the art of troubleshooting. Today’s repairmen are nineteen year old “swap jocks”, who basically pulls an assembly out of a machine and replaces it with another. This process is repeated until the machine magically works. The consumer is then charged for the cost of all the assemblies installed instead of the single assembly which was broken. In most cases the broken part is a small object on the assembly. You can no longer go the television shop and buy a couple “vacuum tubes” to replace and fix the TV. Anyone under thirty will have no idea what a vacuum tube is. I’m advocating that all the “swap jocks” should be replaced by monkeys in white shirts and ties. There would be no change in the mental capability, the repair process would continue as intended and the process would be more entertaining. Assuming the laws of probability the monkeys would repair the machines faster than the “swap jock” about 50% of the time. The world of free thinking, talented repairmen is under assault. Most of these old world craftsmen have gone into hiding. It is possible to seek them out, but they are not easy to find. They are now old men with grey hair in worn faded overalls. If you look hard enough they can be found in the backroom of tired cinderblock buildings with rusted bars over the painted windows. Look for these buildings are far from the interstate intersections. They are most commonly found on the old state highways sometimes called “blue highways”. These are the parts of our cities that were disposed of when the interstate highway made its appearance in the 1960’s. Nestled between the abandon drive up motor lodge and the pawn shop they are hidden. The signs, if any, are old and possibly hand painted.

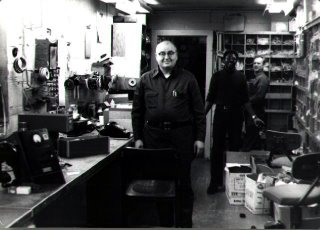

The world of free thinking, talented repairmen is under assault. Most of these old world craftsmen have gone into hiding. It is possible to seek them out, but they are not easy to find. They are now old men with grey hair in worn faded overalls. If you look hard enough they can be found in the backroom of tired cinderblock buildings with rusted bars over the painted windows. Look for these buildings are far from the interstate intersections. They are most commonly found on the old state highways sometimes called “blue highways”. These are the parts of our cities that were disposed of when the interstate highway made its appearance in the 1960’s. Nestled between the abandon drive up motor lodge and the pawn shop they are hidden. The signs, if any, are old and possibly hand painted.

Like searching for druids in Celtic caves, it is easy to identify a true old world repairman’s shop when you enter one. There is a single light bulb hanging from the ceiling without a shade, the type you turn on by pulling a string. A worn dining room chair with the seat replaced and a leg repaired with wire sits behind a huge wooden oak desk. The desk has piles of old faded papers with curled ends that have not been touched in years. Two or three calendars that are a dozen years old, no longer measure time but are used for decoration hang on the unpainted wall. The floor is either scuffed faded checkerboard pattern or rough concrete that has been burnished to a chocolate brown over the years. In one corner of the room is a hound dog that is so old and tired it won’t get up to greet you.

Against the walls are dented galvanized metal shelves with piles of parts in dusty stained cardboard boxes from companies that no longer exist. Scattered on the floor is the evidence of the repairman’s years of study, piles of carefully dissected machine each discarded after revealing their secrets. Like the way doctors use corpses to learn disease, repairmen study broken machines. The wooden counter separating you from the repairman is deeply worn from the thousands of people seeking his wisdom over the years.

Some repairmen’s wisdom is so extensive it may be difficult to understand him. Like reading from some foreign scripture, he will mumble phases long lost to society. “Oh, that’s the model 195B which was replaced in 62 by model 215C with the articulated control arm.” Listening in reverence, the proper thing to do is to smile quietly and nod your head. The mumbling will continue. “Never did like the 195B, thought the 165-FC was a better solution, it came with reversible clutch which allowed….. I think I’ve got one here, somewhere? You ever have seen one?” No need to answer he will continue to mumble regardless of your answer. As the damaged machine is placed on the counter, like a detective he will finally get around to asking you “What’s it doing?” This is your opportunity to speak.

This is the most difficult part of the visit. I come prepared for meeting the repairman, by carefully listening to the offending machine and attempting to articulate the sound of its malaise. It is like trying to talk to Einstein using only baby talk. Realize, you will never say anything remotely intelligent to the repairman. Grunting and pointing at the machine with a puzzled look like a big ape usually works the best for me. Otherwise you end up saying something childish like “When the black piece hits that thing there in makes a clump-clump sound.”

All good repairmen will show enough respect to allow you to think for a brief second that you communicated something of value. In reality, the fly buzzing against the window behind you is having an equally useful conversation with the repairman as you are. Behind the quiet façade his mind is inspecting the machine and visualizing all of the parts functioning in concert. After you have finished whatever prepared diatribe you feel you need to convey, he will turn his back on you and walk to the metal shelves mumbling some other long lost phase. “Sonny, you remind me of Bob on Maple, he had a problem with his 49M-3 decided to leave it here and buy a new 1800EM, never worked worth a damn.”

After a moment of silence, the mumbling will begin again. “I’ll bet you the gasket is interfering with the idler control screw. I saw that happen all the time with the 217-DC. What we use to do it replace it with an o-ring from the 383-XL, since they stopped making parts for the XL in 78, I substitute the gasket from a 478-CA.” Again this is the proper time to smile and nod. Any stupid comment at this point will disrespect the process and may cost you the “you are an idiot service charge of $25”.

The conversation will begin to conclude as the repairman roots around on the metal shelves. “Now was that part number 29481C? No it was 29497D.” As you look at the stacks of parts catalogues discarded in the corner, you realize they are like old newspapers that have been read and contain no information that the repairman doesn’t already know. The catalogues are for your entertainment, no one else. The repairman perfectly in harmony with his environment will reach into a half rotten cardboard box and pull out a rubber gasket wrapped in clear plastic. He will walk back to the counter grab a pair of pliers hand forged during the first industrial revolution and begin to perform surgery on the machine before your eyes.

There will be a couple small grunts as he struggles with accumulation of rust and scale, but after three minutes the old broken part will discarded and replaced with a part from another machine that even the original manufacturer doesn’t know will work. Finally he will look up at you and smile “That should keep it going for another ten years.” As he gently lays the machine back into your arms you ask what you owe him. He turns to gaze at the calendars that are reminders of years gone by and says “That’s going to be $2.78 today, Sonny.”

Leaving the shop you ask yourself “What will happen to the world when we lose the last of these aging forgotten wise men?” The future is bleak. We will never be able to replace these bastions of knowledge with the hordes of pimpled faced “swap jocks” from Circuit City. Whatever the future, I guarantee I’ll be the last person they drag screaming and kicking into this disposable society.